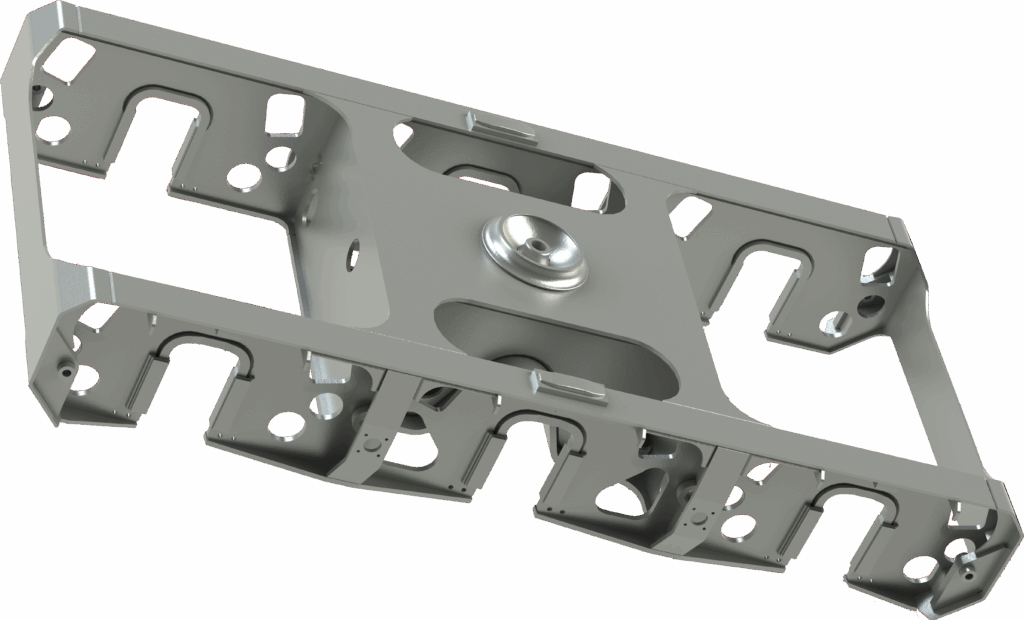

Excellence in high-technical and high-volume metal processing from raw material to full welded assembly components

Métalhom specializes in laser, plasma, and oxy cutting, as well as the processing of complex metallic parts with high technical requirements.

We support high-volume industrial clients with tailored solutions, from raw steel to finished assemblies, combining repeatability, precision, and cost-efficiency.

NUCLEAR

CONSTRUCTION

MINERAL INDUSTRY

LIFTING

HANDLING

RAILWAY

HVAC ENGINEERING

YELLOW GOODS

AGRICULTURAL

OIL & GAS INDUSTRY

MACHINE TOOLS

DEFENSE

Services

Industrialization & Engineering Expertise

To serve the complex needs of our industrial clients, our engineering team focuses on smart industrialization, optimizing both materials and processes to enable efficient, high-volume production with repeatable quality.

Our engineers work with state-of-the-art CAD, CAM, ERP and PHL tools, always striving for continuous process improvement and aiming for optimal quality and service.

Shot blasting

To ensure fast and reliable supply, Métalhom maintains a substantial material inventory with a permanent stock of 10,000 tonnes of steel (structural, high yield strength, abrasion-resistant, pressure vessel, ballistic, etc.).

All materials are recorded, classified, and documented, ensuring full traceability—a key priority across all stages of our process.

To improve the quality of the finished part, all materials are systematically pre-treated using a shot blasting machine with 8 turbines, 3,200 mm width, 15,000 mm length, and an annual capacity of 40,000 tonnes.

Capabilities

FLAT PRODUCTS

- 7,000 m² stock area for heavy and large-format sheets, 8,000-tonne capacity, 16-tonne handling capability

- Stock area for medium thickness and large format sheets, 1,500-tonne capacity, 16-tonne handling

- Automated warehouse for medium thickness (1,500 x 3,000 mm), 600-tonne capacity

- Pallet racking for thin sheets (1,500 x 3,000 mm), 100-tonne capacity

LONG PRODUCTS

- Storage for long products up to 12 m, 150-tonne capacity

- 5-tonne handling capacity

MATERIAL HANDLING

- Various jib cranes and handling systems (0.25 to 4 tonnes)

- 12 overhead cranes (single and double girder) ranging from 3.2 to 16 tonnes

- 1 forklift, 16 tonnes

- 8 forklifts from 2 to 5 tonnes

Cutting

Métalhom is equipped with modern industrial machinery for both thermal and mechanical cutting processes.

In a spirit of innovation and responsiveness to market needs, our team co-developed the world’s first XXL bevel fiber laser cutting machine with dual heads.

This unique system enables simultaneous cutting of two plates on tables measuring 5,500 x 13,000 mm.

Capabilities

LASER CUTTING

- 2 TRUMPF fiber lasers, 1,500 x 3,000 mm, automatic loading, 10 kg capacity with automated medium thickness warehouse (600 tonnes)

FIBER LASER BEVEL CUTTING

- TRUMPF 6 kW laser source

- 2 bevel heads, dual-pallet

- Dimensions: 5,500 x 13,000 mm, pendulum mode

PLASMA CUTTING

- 600 amps

- 2 bevel heads

- Dimensions: 5,500 x 20,000 mm

OXY-FUEL CUTTING

- 1 cutting table, 8 torches, dimensions 5,500 x 24,000 mm

- 1 heavy-duty cutting table, 4 torches, dimensions 5,500 x 10,000 mm

PUNCHING

- 1 turret punch press, 40 tools, 1,250 x 8,500 mm

Finishing operations

Within its 12,000 m² facility, Métalhom operates a comprehensive finishing line including deburring, shot blasting, leveling, and packaging in a continuous and automated flow.

This setup enables the delivery of high-quality parts without added cost for the client, fully aligned with the market trend toward complete outsourcing of complex technical projects.

Capabilities

- A complete finishing line capable of processing high volumes of parts coming from nitrogen laser cutting. The line includes a dedicated flipping unit for full panoply rotation, a grinding machine, a dimensional inspection station, and a robot for automated unloading and conditioning.

- 1 automatic part shot blaster, 1,600 mm wide, 4 turbines, manganese steel belt

- 1 automatic leveler, 19 rollers, 2,000 mm wide, 40 mm thick

- 1 200-ton leveling press, 2,000 x 5,000 mm, 8 cylinders

- 1 50-ton leveling press, 8 cylinders

- Sheet shot blaster: 8 turbines, 3,200 mm wide, 15,000 mm long, 50,000 tonnes/year (16-tonne handling)

- 2 semi-automatic beveling boxes

- 1 semi-automatic beveling machine, max bevel 15 x 15 mm

- 1 automatic saw, Ø350, 12,000 mm length

- 1 70-ton punch press

- 1 automatic deburring machine, 2,000 mm wide

- 2 automatic deburring barrels, 500-liter capacity

- 1 manual deburring barrel, 100-liter capacity

Forming

With press brakes up to 14,000 mm (46 ft) long and 1,600 tons, Metalhom handles oversized steel parts with unmatched forming power.

Equipped with laser angle control and automated back gauges, our forming lines ensure consistent bending across large production runs.

Thanks to automated loading/unloading systems, we maximize throughput while maintaining tight tolerances, even on the most demanding geometries.

Machining

Metalhom delivers fully welded subassemblies up to 8,000 mm (26 ft) and 16 tonnes, ready for direct integration into your equipment.

We combine robotic welding cells (dual-station, 2-heads) with manual booths equipped with hydraulic rotators, ensuring both productivity and flexibility.

This setup guarantees consistent welding quality across batches while optimizing cycle time thanks to simultaneous loading/unloading in hidden time.

Welding

Métalhom offers a complete solution including forming, machining, beveling, bending, and assembly, enabling customers to outsource primary parts at optimized cost, quality, and traceability.

Surface Treatment

Métalhom relies on a network of rigorously selected partners, chosen for their quality processes and CSR commitment.

These subcontractors can also provide logistics support for implementing just-in-time systems at our clients’ sites.

Kits I Logistics

Our logistics team offers kitting solutions with delegated inspection, labeling and delivery both within France and internationally, using various delivery methods and scheduling systems (just-in-time, kanban, etc.).

Métalhom also provides custom containers suited to all delivery formats (e.g., line-side delivery).

At a Glance

Tons of materials in stock

Parts produced per year

Tons cut per year

Service rate

Production sites: France & Portugal

Recycling rate

Accreditations & Partners

Métalhom: Committed to Social, Environmental, and Economic Responsibility

Métalhom has defined its overall strategy in alignment with the CSR commitments of its management, clients, and employees.

Through a collaborative approach, the company is actively engaged in social, environmental, and economic initiatives.

Contact Us

We would be pleased to discuss your needs.

Please don’t hesitate to contact us using the information below.